Geotechnical Instruments have a monumental role to play in the continual productivity and safety of the mine, whether underground or on the surface. The geological formations are highly influenced and impacted by mining, and therefore, these formations also have an effect on mining.

Encardio Rite offers a variety of underground mine monitoring and open-pit monitoring instruments for the measurement of deformations, groundwater, strain, stress, and load. These monitoring sensors have proven to be extremely reliable and can work efficiently with high performance under harsh conditions. It provides accurate and important quantitative data regarding the behavior of the surrounding rock/ground, the performance of the ground support systems, the safety and stability of the underground mining work, and the excavation progress.

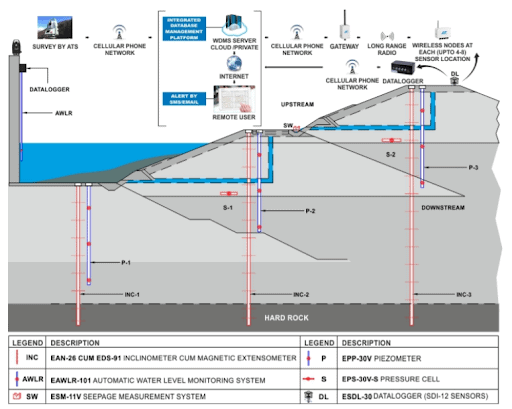

The online web-based underground mine monitoring service provided by Encardio Rite is well-equipped with automatic alerts and warning systems for the early detection of ground failures and other mishaps. The use of advanced technologies like automatic 3D deformation monitoring using ATS, laser scanning, and aerial surveys using drones makes for an infallible monitoring plan.

Benefits of Monitoring Mines

Underground mine monitoring and risk assessment have the following benefits:

1. Improve Safety – It helps to maintain safe operational systems and procedures and guard personnel, materials, nearby structures, communities, and the environment. If there is a potentially unstable ground, it provides timely alarms.

2. Economical – Geotechnical Instrument helps in the optimization of mine operations. For example, increasing the steepness of slopes to minimize waste removal and increase recovery of ore helps to keep an eye on the slope movement and the surrounding ground.

3. Control & Remedy – Having a mine monitoring plan assists in providing an alert on any expected failure zones, developing and designing appropriate remedial action plans, and safely evacuating the area without any life loss.

4. Confirm Designs – Evaluating the performance of the ground support system, stability of underground mining operations, and slope designs.

5. Assessing Impact of Natural Events – Produce accurate information and details of the impact of events such as earthquakes, excessive rainfall, etc to help minimize the risk associated.

6. Regulation compliance - To conform to the current and future standards & regulations for safety.

7. Future Understanding – Preserving a history of information helps to identify different rock/soil/slope behaviors over a long period of monitoring.

| Also Read: Consolidation of Soil: Instrumentation & Monitoring |

Underground Mine Monitoring Solutions

The Encardio Rite-Solutions for online monitoring of mines include:

- Geotechnical sensors measure all relevant and essential parameters in different types of mines.

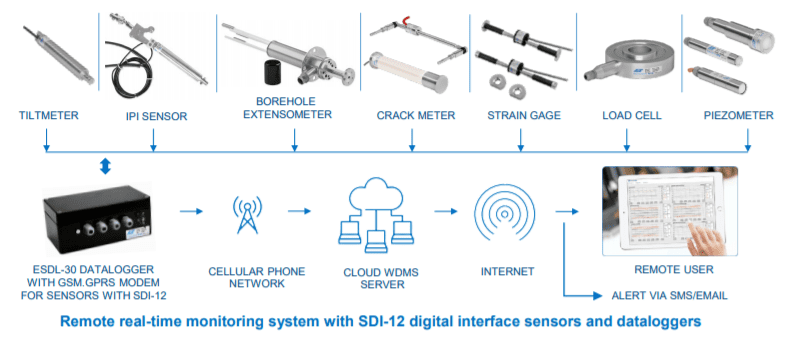

- Automatic monitoring of geotechnical sensors with SDI-12 Digital interface using data loggers with GSM/GPRS telemetry.

- Automatic monitoring using LoRa nodes and gateways.

- Geodetic monitoring using automatic total stations (ATS) with GSM/GPRS telemetry

- Laser Scanning

- Using UAVs(Unmanned aerial vehicle) or drones for survey

- Making use of a Public cloud-based web data management service (WDMS) to provide online data with alarms to the authorized personnel at different locations.

The advances and progress in technology have enabled geotechnical instrumentation, geodetic survey, and data transmission systems to monitor the mining work performance from any remote location. Data Loggers and total stations pick up the reading from the installed sensors at selected intervals. If any of the readings are above the predetermined trigger values, an alarm or an SMS is sent to the authorities. All the data collected by the sensors are transmitted to a remote data management software, at a central server or cloud, where they are processed, evaluated, and presented. The same becomes accessible to the concerned authorities, at their desk or mobile devices through the World Wide Web.

| Also Read A Guide on Geodetic Survey and Monitoring |

Geotechnical Sensors for Mine Monitoring

Encardio Rite offers a variety of geotechnical sensors for surface and sub-surface online monitoring of mines. Let’s take a look at them:

| Parameter | Instrument | Application Area |

Sub-surface |

| Sub-surface lateral movement (automatic) | Encardio Rite Model EAN-52M Vertical In-place Inclinometer system is equipped with several biaxial probes along with SDI-12 output. These are connected in a chain manner for continuous monitoring of subsurface lateral movements. | Open-pit mines-around excavation, in slopes Tailings dam, in the fill area. |

| Sub-surface lateral movement (manual) | Model EAN-26-MV is a manual inclinometer system containing a bi-axial digital inclinometer probe, an operating cable on a reel with a Bluetooth transceiver, and a smartphone datalogger with an inclinometer application. |

| Sub-surface movements unidirectional | For accurate monitoring of sub-surface movement, Model EDS-70V vibrating wire type multiple point borehole extensometer is used. | Open-pit mine: Horizontal Installation at the face of the excavation Underground Mine: Vertically upward and near-horizontal installations inside the mine |

| Yield-point’s d-EXTO Mk II multipoint borehole extensometer with up to six (6) Linear Variable Induction Transducers (LVIT). |

| Sub-surface movements (x, y & z) | In-Place Inclinometer(Model EAN-62MS) is used for the measurement of 3D(X-Y-Z) of gage well/borehole | Open-pit mines-around excavation, in slopes

Tailings dam, in the fill area |

| Pore pressure | Model EPP-30V vibrating wire piezometer is used for the pore pressure variation monitoring during fill or excavation. The piezometer is made suitable for multilevel installations in a single borehole using the fully grouted method. The grout restricts the intake zone for the piezometer, preventing the migration of water upwards or downwards through the borehole. | Tailing dam, infill, and foundation Open-pit, around excavation in slope stability investigations. The underground mine, in rock mass around the excavation. |

| Water level | Model AWLR 101 automatic water level recording system | In the observation wells within the body and around the tailing dam for the measurement of the water level. |

|

Surface Instruments |

| Tilt | Model ESDL-30MT or EAN-95MW tiltmeters are employed to record changes in slope inclination nearby cracks & areas of maximum anticipated rotational movement. | Open-pit, slope stability monitoring. For monitoring nearby structures and assets such as transmission towers. |

| Displacement | Model EDJ-40V Crack and Joint Meters are used for the monitoring displacement/opening of cracks in the rock mass | Open the pit, to monitor any crack opening |

| Anchor load | Model ELC-30S/ELC-30SH is a Resistive Strain Gauge type center hole load cell that monitors the tension in anchors and rock bolts used in the stabilization of the slope or tunnel lining. | Open-pit – on anchors located in slopes Underground mine – on anchors placed in rock mass around the excavation area |

| Convergence | With the help of an automated total station (ATS) and control box, Model ERT-20P2 mini prism target is used to monitor 3D deformations | Around the excavation in Open-pit and slope to monitor slope stabilization/deformation |

| Stress | Model ESC-30V Vibrating wire shotcrete pressure cell or model EPS-30V-C vibrating wire concrete pressure cell is employed for the monitoring of radial and tangential stress in shotcrete lining | The underground mine, the stress of rock mass around excavation, hoop and radial stresses in concrete tunnel linings/shotcrete |

| Model EPS-30V-S Soil Pressure Cell for stress monitoring on plane surfaces | Open-pit, in raft foundation Tailings dam, fill, and foundation to monitor total and differential pressure |

| Model EPS-62V borehole stress meter for the measurement of stress changes in rock | In the boreholes holes drilled into the walls of stopes/underground mines, the slope of an open mine |

| Strain | Model EDS-20V-E embedment or EDS-20V-AW arc weldable strain gage | Underground mine – tunnel lining, in case of permanent tunnel construction Long-distance pipelines conveying concentrates out from the mine to the processing plant |

| Seepage | Model EGS-30V seepage monitoring device | Tailings dam, seepage channels |

Notes regarding underground mine monitoring & instrumentation:

- Encardio Rite offers a variety of shielded armored/non-armored cables ranging from 2 to 40 cores for connecting sensors to the readout units. Splicing kits, junction boxes, switch boxes, protective enclosures, and covers, and lockable manhole covers are immediately available for the most simple to the most complex instrumentation schemes. Encardio also allows the reduction of cable lengths with the help of multiplexers, SDI-12 interface, and wireless transmission using the allowable RF band.

- Grouting is the most essential and crucial factor that affects the quality of readings post-installation. Since improper grouting cannot be fixed, experts should be involved in the grouting process for borehole instruments.

- There is a necessity for lightning protection as the field instruments are vulnerable to lightning damage and are placed with a high rate of lightning strikes. As the cable length increases, the risk also doubles. Most Encardio Rite sensors make use of tripolar plasma surge arresters to protect against voltage spikes in the input leads. However, an additional lightning protection system is still very much recommended. Engage a local agency specializing in earthing and lightning protection systems to implement the same.

- In cases where the field instrumentation is required to be connected to the client’s existing local network based on fiber optic cables, Encardio Rite provides ethernet interface NL2-1.

This brings us to the end of our article on underground mine monitoring and instrumentation. If you have any doubts, questions, or queries, feel free to comment below.