The Encardio Rite Model EAN-90M MEMS Tiltmeter plays a crucial role in the monitoring of inclination and vertical rotation in a variety of structures, including but not limited to buildings and dams. This device is engineered to withstand the rigors of construction activities, ensuring that it continues to function effectively even in challenging environmental conditions.

One of the standout features of this tiltmeter is its high-resolution measurement capability. It can accurately capture and report subtle changes in inclination and vertical rotation, providing valuable data for assessing the stability and structural integrity of the monitored sites. Whether it's detecting minute shifts in the tilt of a building or changes in the orientation of a dam, the EAN-90M excels in delivering precise measurements.

Principle of Operation:

The Model EAN-90M Tiltmeter has a stainless steel housing that has an accurate accelerometer and proper signal conditioning circuit mounted inside it.

The accelerometer picks up the force due to gravity which is at its highest when the accelerometer is rotated to the tilt position of 90-degree and lowest(zero) when the angle of tilt is zero. For all the other tilt angles, the accelerometer force can be determined by the product of the sine of tilt angle and acceleration due to gravity.

The tilt sensor thus provides a bipolar DC voltage output proportional to the sine of the tilt angle measured by the tiltmeter. The output is measured as zero when it is placed in an accurate vertical position. Even though the sensor gives a moderately low-cost tilt measurement, it provides excellent resolution, long-term stability, and low thermal sensitivity. With the use of suitable mounting accessories which include brackets and anchors, the MEMS tiltmeter can be secured on any vertical surface, horizontal floor, or ceiling.

The difference that has to be understood here is that the Model EAN 90-M is not designed for the complete determination of tilt in structures. It is used to measure the change in the tilt of a structure to which the sensor is attached.

To calculate the change in the tilt of the structure, the initial tilt reading when the instrument has been placed on the structure is recorded and subtracted from the subsequent tilt reading.

Tool and Accessories

The following tools and accessories are required for the proper installation of the tiltmeter.

- Power drill

- Concrete / Masonry drill bit 8 mm

- Spanner 8/9, 12/13 mm

- Allen key 5 mm

- Cloth for cleaning

Read More: What Are Tiltmeters and Where Are They Used?

Installation of Tiltmeter

The MEMS Tiltmeter can be mounted on a vertical surface, swung from the ceiling, or placed on the floor with the help of a suitable mounting arrangement/bracket available from Encardio Rite as optional accessories.

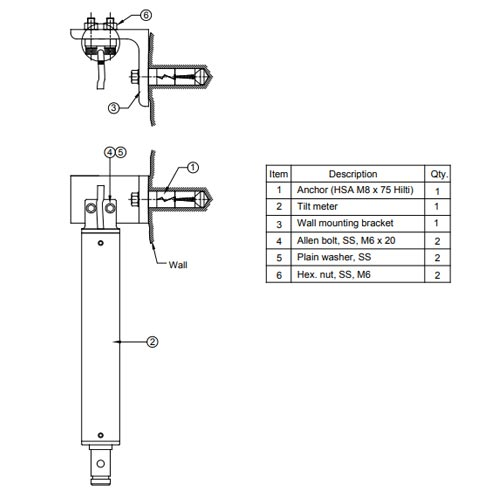

Let’s look at the procedure to install the instrument on a vertical surface.

- Identify the wall where the change in the tilt has to be measured. Using a drilling machine, dig an 8 mm Φ x 50 mm deep hole for Hilti anchor HSA M8 x 75 or equivalent.

- Insert anchor in the drilled hole.

- Once the anchor is placed accurately, install the tiltmeter bracket on it and secure it tightly.

- Set the MEMS tiltmeter on the installed bracket with two M6 x 20 mm Allen bolts.

- Once the above steps are done, connect the tiltmeter with the readout unit.

- Tighten the anchor and Allen bolts/nuts so that the tiltmeter reads almost vertically on the read-out unit.

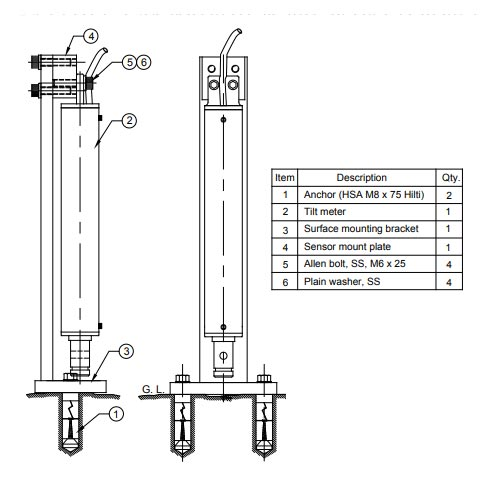

Let’s have a look at the Installation on the horizontal surface

- Trace the placement of the two mounting holes using the mounting bracket as a template.

- Visually ensure that the two-hole positions are almost aligned along the axis at which tilt has to be measured.

- Using a drilling machine, dig an 8 mm Φ x 50 mm deep hole for Hilti anchor HSA M8 x 75 or equivalent.

- Once that is done, place the anchors in the drilled holed.

- Mount the tiltmeter bracket on the anchor and secure it.

- Fix the tiltmeter on the mounting bracket with two M6 x 20 mm Allen bolts.

- Connect tiltmeter with read-out unit.

- Tightly secure the anchors & Allen bolts/nuts to ensure that the tiltmeter reads almost vertically on the read-out unit.

Read More: Tiltmeter: How Does it Work, Installation, & How to Read

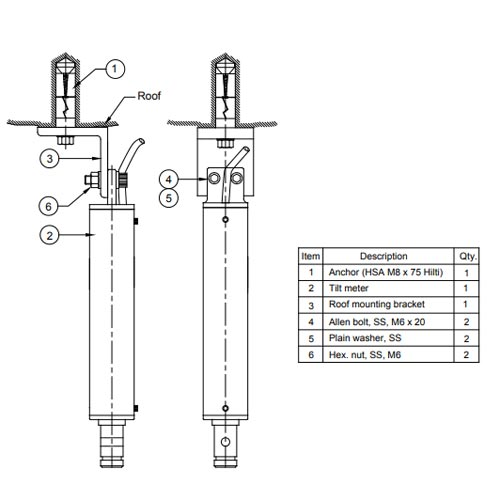

Let’s look at the procedure to install the tiltmeter on the roof

- Drill an 8 mm Φ x 50 mm deep hole for Hilti anchor HSA M8 x 75 or equivalent on the roof at which change in tilt has to be measured.

- Once that is done, place the anchors in the drilled holed.

- Mount the tiltmeter bracket on the anchor and secure it.

- Fix the tiltmeter on the mounting bracket with two M6 x 20 mm Allen bolts.

- Connect tiltmeter with read-out unit.

- Tighten the anchor and Allen bolts/nuts so that the tiltmeter reads almost vertically on the read-out unit.

Measurement of Tilt

Encardio Rite Model EDI-53UTM portable digital read-out unit/data logger is used to read the output of the MEMS Tiltmeter. The output can be obtained from a remote location too by using an automatic data acquisition system like Encardio Rite model EDAS-10.

The tiltmeter is equipped with a 2m built-in six-core cable that can be discontinued or extended to the nearest measurement station through a suitable junction box.

When using with Encardio Rite model EDI-53UTM portable digital read-out unit, a break-out box (special junction box) having a suitable circular connector is available.

Wiring Details

| Cable Colour | Description |

| Red | +12V DC |

| Black | -12V DC |

| Green | 0V (Power Supply Common) |

| Blue | Output Channel A |

| Brown | Output Channel B

(only for biaxial tilt sensors) |

| White | Output Common |

Connecting Sensor to Encardio Rite Digital Readout Unit

Using a break-out box, connect the tiltmeter to the Encardio Rite model EDI-53UTM portable digital read-out unit/datalogger. The mating circular connector to the read-out unit is accommodated in the break-out box. Along with the connecter, it also contains a lightning arrestor.

Encardio Rite model EDI-53UTM portable digital read-out unit/datalogger reads sine of tilt angle when the parameter of typical tiltmeter is fed.

To read the sine of tilt angle, set up the EDI-53UTM channel as follows:

| Unit [UNITS] | units (key 9) |

| Initial reading [IR] | Set to zero |

| Gauge factor [GF] | 2/tilt meter gage factor in volts/sin 90° |

| Coeff of X² | Set to zero Decimal point [DP] As required (recommended value is 4) |

The tilt angle can be calculated by sin-1(observed value). For the bi-axial tilt meter, set up two channels (one for the A-axis and one for the B-axis) in a similar manner.