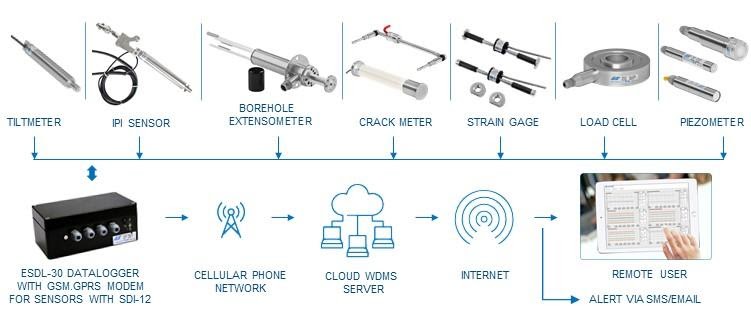

The usage of instruments and field measurements is extensively on the rise, especially for optimized construction control and safety monitoring. The increased demand has led to the need for a cost-effective instrumentation monitoring network system that would allow monitoring of various parameters but within budgeted walls.

Apart from the cost-effective nature of instruments, it is also crucial to have sensors that allow the access of data in real or near real-time anywhere on the globe. The presented data should not just be the instantaneous value, but also easy to understand and depict the variations over a predefined interval of time. Further, there is also a need to have an alerting system that goes off before the catastrophic event takes place, giving enough time for the authoritative person to take remedial measures.

The advancement of technology and human capability has introduced us to some of the finest equipment that is more precise, reliable, cost-effective, and tailor-made for every challenging field. In this article, we will be looking at some of these advanced and futuristic technologies that aim to change the face of monitoring.

1. Digital Sensors

Sensors play a crucial role when it comes to monitoring. Even though there are several sensors available in the market today, the traditional sensor uses the same kind of network to produce the data and output. To put it simply, traditional sensors are bound in a typical instrumentation network with the help of a central data acquisition system (DAS). The DAS takes in the input from the sensors and then makes use of multiplexers to produce the output in suitable engineering units. This output is then stored in the internal memory of the DAS and is retrievable by a PC.

The era of digital sensors has changed it all. The new system makes things considerably easier by adopting a single 3-conductor cable that seamlessly connects all the sensors and data loggers in a serial bus. The digital aspect of the sensor allows it to produce accurate output that is not disrupted by the cable length running between the sensor and the datalogger.

Furthermore, the digital sensors collect the calibration parameters inside the sensors and present the output directly in terms of suitable engineering units. This makes them smart sensors.

Another advantage of digital sensors is that it has a very low power requirement and can connect with any suitable data logger to create a robust sensor network for efficient monitoring.

With the recent advancement in technology, you can use a single brick-sized data logger for up to 180 digital sensors. The data loggers make use of a couple of lithium batteries. The battery is designed to last for more than two years if the data needs to be collected several times a day and transmitted once/daily to the cloud-based data monitoring system. If you are using a lower number of sensors, the batteries can last almost 5 years.

To connect to the internet, you would need a cellular service provider’s data SIM card. The data logger works in a scheduled manner, wherein it has a specific time to sleep and wakes up at the designated time to collect the data and transmit it to the cloud at intervals. However, the location should have an active cellular service network to make it possible.

Read more: Type of Data Loggers and How Do They Work?

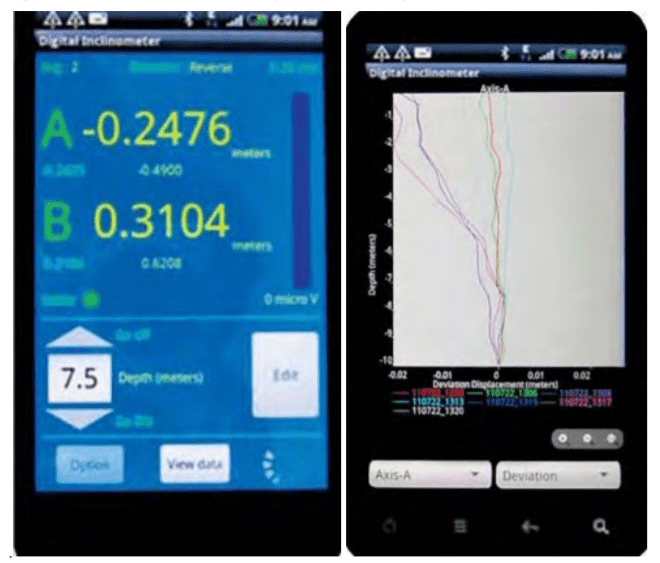

2. Using Mobile Phones as a means of Data Collection

While we are discussing the future and technology of instrumentation and field measurements, it is necessary to address the evolution of the means of Data Collection. From handheld readout units to palmtop computers, analog, and digital sensors have used it all to arrive at a conclusive output monitoring. However, the advent of mobile phones has changed it all!

With the advancement in mobile technology, we have evolved compacted devices that feature high-resolution large colour graphics display, internal memory, Bluetooth, Cellular phone coverage, high-resolution camera, internet connectivity, built-in GPS, and many more. As it is evident, the devices find their application in the data collection field for geotechnical or civil engineering safety instrumentation networks.

Modern, high-end mobile phones easily determine the sensor location with the help of the built-in GPS sensor, without requiring the help of a surveyor. Furthermore, the video recording ability of the mobile phone makes it easier to record the installation of sensors, and in the case of sophisticated sensors, it can also serve as a training video.

The mobile phone also makes for a consolidated option as the different application software needed for the various types of digital sensors or DAS can be downloaded on a single device. This negates the need and the cost that would be spent on many different readouts/dataloggers.

Moreover, Mobile Phones operate with a standard system like Android which provides the user with a magnitude of options to choose from, and one can easily get on in their budget. If you face any difficulties or issues with a certain type of mobile phone, you can easily change the device and transfer the memory card from the old one to the new one.

3. Wireless networking (RF)

Wireless sensor networks are vital in monitoring construction sites, large structures, and landslide areas. They are extensively used in applications where geotechnical and other sensors are used for data collection and transfer to a central server for access by multiple users.

The innovative long-range radio network solution allows real-time monitoring of geotechnical and structural sensors in challenging conditions with reliable data transfer without any delay. With real-time data collected from the wireless system, the project owner, consultants, and contractors remain aware of the slightest change in the data. An early warning system allows timely decisions, increased safety, reduction in project delays, and consequently cost-effectiveness.

In the wireless monitoring system, the sensors are interfaced with the long-range, low-power wireless network through nodes that send recorded data to the Gateway with utmost reliability. Gateway uploads the collected sensor data to the central/cloud server.

The long-range radio frequency-based wireless data collection network provides complete automation of monitoring with seamless connectivity in large construction sites, tunnels, and landslide projects. The wireless system eliminates the need for running lengthy cables. It is especially useful at locations where sensors are distributed over wide areas and running cable lengths to long distances can be tricky and/or at locations where construction activity can damage the running sensor cables.

Read more: Emerging Technologies in Tunnel Instrumentation and Monitoring

4. Distribution of Processed Data over the Internet: Web-based Data Monitoring Service (WDMS)

Almost every Civil Engineering Project involves many stakeholders who are invested in the safety status of the project. It becomes important to provide the stakeholders with all the relevant information as well as near-real-time access to data. This is crucial to understand the potential hazardous development and to make an informed and remedial action without any delay.

Modern technology has allowed for the availability of proprietary software that can be hosted on servers connected to the Internet. Advanced software like DRISHTI is designed to collect data from multiple sensors and data loggers used in a project over copper cables, optical fiber cables, or various types of RF links according to a preset schedule. The collected data is presented in a set of meaningful graphs or tables, in sync with the parameters being monitored by multiple users all across the world, performs the required calculations, and fetches the historical data as well. The collected data is also securely added to a database.

The software also allows setting different alarm thresholds, which, if crossed, issue an alert to the person in charge through an email or SMS. Most of the software allows setting up to 2 alarm levels that depict that the parameter has exceeded the alert level and needs remedial action.

Cloud-based Web Data Monitoring Service (WDMS) seamlessly connects users from an internet-connected computer located anywhere in the world, to monitor the instrumentation data remotely. The authorized users are allowed to view any data or reports of the project simultaneously.

The most essential feature of the WDMS system is that it uses GSM/GPRS cellular services to transfer data from the individual data loggers wirelessly to the remote monitoring computer (host).

An important feature of the WDMS system is the use of GSM/GPRS cellular services to transmit data from the individual data loggers wirelessly to the remote monitoring computer (host). With a reliable GSM/GPRS cellular service, the data loggers can be located virtually anywhere in the world.

WDMS can also be used in projects where multiple data loggers are used or when the individual data logger is spread over a wide geographical area. The database management system also supports data uploaded manually in case manual methods of data collection are used.

5. Automated Monitoring System (AMS) of Real-time Total Displacement (3D)

An automated monitoring system is designed with a series of networked robotic total stations and prisms located along the Project’s alignment. The measurements are captured with the help of a series of automatic total stations of high precision which record the displacement of the reflecting prisms on the ground surface and buildings.

The AMS secures the valuable and timely monitoring of the displacements, provides high measurement density, simultaneous wireless transmission, and entry of the results into the database system to ensure the minimal time between their reading and their

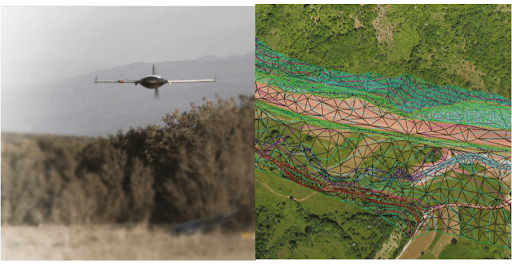

6. Topography

The main goal of advanced technology is to reduce manual and strenuous work and introduce a more reliable and accurate method of monitoring. Aerial mapping has considerably eased the process of topographical surveys, construction progress monitoring, and pre-construction surveys over large (or difficult-to-reach) areas. Making use of both visual inspection and inspection with spatial information considerably minimizes the need for personnel visits.

Visual inspection presents an extensive view of the visuals along with data, photos, orthophotos, and videos that make it easier to observe the development, whereas spatial information allows viewing the values and accurate data.

The accuracy that can be achieved corresponds to a survey scale better than 1:500 for UAVs (fixed wings) and 1:100 with a drone (octocopter).

Some of the benefits of Aerial Mapping are:

- It results in reduced personal visits and instead allows the same kind of interaction without physical meetings.

- Makes the complete information available online in a short time, even from non-accessible areas.

- Aerial Mapping reduces costs but does not compromise the quality of the survey.

- Poses as a safer option when dealing with unstable and dangerous areas.

UAVs with fixed wings are preferred to be used at 400-600m above the ground level to produce a Ground Sampling Distance of 8 – 12 cm which is suitable for almost all earthworks and surface surveys. As for viaducts, bridges, or other structure surveys, flights can be undertaken with drones (octocopters) providing vertical and oblique images, from a close distance of a maximum of 50 m.

7. Laser Scanning with state-of-the-art analysis software

Laser Scanning is an advanced and fairly new mapping technique that is used for the geometric documentation of buildings, architectural, and archaeological monuments, construction projects (such as tunnels, bridges, dams, etc.), or any other construction that requires a high degree of analysis, is inaccessible or difficult to access or must not be touched.

It is based on a very dense three-dimensional coordinate map of the surface areas to be mapped in the fast output of several thousand to one million points per second. It analyzes all kinds of objects and collects data on their shape and possibly their appearance (e.g. colour).

OPSIS is an advanced data analysis software that processes 3D data collected by a laser scanner. It optimizes the huge data from the laser scanner and provides an analysis directly from the 3D data for accurate and fast monitoring of deformations. With OPSIS one can have complete deformation overview maps, time-displacement graphs, and animations depicting deformations occurring with time, in a snap!

Read more: Structural Health Monitoring: Instrumentation & Monitoring During Construction

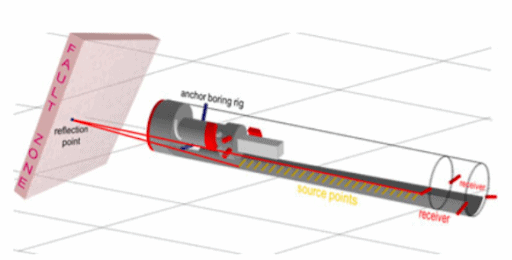

8. Tunnel Seismic Prediction (TSP)

With the recent development, the seismic methods of predicting rock conditions up to 150 m ahead of the tunnel face have significantly improved. The range stands at around three times more than what can be achieved by probe drilling on the face of the tunnel. Furthermore, TSP does not interfere with tunneling, and you do not need to stop the TBM during the test process.

9. Fibre Optic Solutions

We are witnessing an increase in the use of optical fibers to monitor the structural health and geotechnical conditions of infrastructure projects within the Mining, Civil Engineering, and Geotechnical fields of activities. The technology is largely employed to monitor the change in strain and temperature, with the help of a single optical fiber cable over large lengths and areas at many locations in the world.

In this article, we spoke about the recent trends and advancements in the field of topographical surveys, sensor technology, laser scanning, surveying using automatic total stations, tunnel seismic prediction, fiber optic solutions, data transmission, data recording and presentation in field instrumentation employed for monitoring of geotechnical and structural engineering parameters in various civil engineering projects.

It is essential to keep a watch on new technologies as they can considerably increase the accuracy of measurements as well as reduce costs.