Geotechnical Instrumentation and Monitoring are a sub-branch of Geotechnical Engineering. You can think of it as a huge umbrella that shades all the prominent construction projects ranging from tunnels, high-rise buildings, deep excavations, and boreholes, to airports, seaports, railways, dams, and bridges.

Geotechnical monitoring can be done for both the short-term as well as the long-term safety of the structures. It is carried on essentially during the pre-construction, construction stage, post-construction as well as in the dilapidation stage.

Here we are going to talk more about the geotechnical instrumentation and monitoring along with all the different types of instruments and services that Encardio Rite has to offer.

What is Geotechnical Instrumentation?

The word ‘Geotechnical’ is made up of ‘geo-‘ and ‘technical’ which means anything specifically related to the earth. Hence, geotechnical instrumentation refers to all the different sorts of instruments that are used to monitor the earth, structures constructed over it, beneath it, and on it. It encompasses the entire spectrum of monitoring anything that is constructed and maintained.

The geotechnical services make use of instruments that include inclinometers, piezometers, tilt meters, beam sensors, joint meters, crack meters, strain gauges, pressure cells, load cells, plumb lines, borehole extensometer, magnetic extensometers, seepage measurements, reservoir level meter, seismographs, portable readout units, an automatic data acquisition system, etc.

Read more: Instrumentation & Field Measurements: The Future

What is Geotechnical Monitoring?

Tunnel Monitoring

Tunnel MonitoringGeotechnical Monitoring goes hand-in-hand with geotechnical instrumentation. For instance, whenever a structure is planned, a proper surveying of the construction site as well as the nearby site is carried out. A Geotechnical Survey is essential to check the soil profile and groundwater level before constructing any structure.

Once the construction work begins, continuous real-time monitoring is carried out so that the structure is made as per the expectations. Even after the completion of the project, constant monitoring and geotechnical surveys are carried on to gauge the structural changes.

All these processes are termed as geotechnical monitoring.

Geotechnical Instrumentation And Monitoring Companies

There are several companies around the world that deal with Geotechnical Instrumentation and Monitoring. Remember, that there’s a huge difference between civil engineering or a construction company and a Geotechnical Instrumentation and Monitoring company.

One such company is the Encardio Rite Group. Established in Lucknow, India in the year 1966, Encardio Rite Group is a World leader in safety monitoring providing geotechnical instrumentation, structural & environmental monitoring along geodetic surveying solutions. Over the years, it has become an established brand for its specialized services with high-quality products and innovative online solutions.

Encardio Rite provides the most comprehensive range of Geotechnical services and products including data collection, database management, complex monitoring, surveying, installation, supply, and calibration of geotechnical and geodetic instrumentation with in-house developed advanced software.

Facilities In A Geotechnical Instrumentation And Monitoring Company

Geotechnical Instrumentation And Monitoring

Geotechnical Instrumentation And Monitoring

Any Geotechnical Instrumentation and Monitoring company must have precise, reliable, and accurate monitoring as well as instrumentation services. When it comes down to structures, we can’t take a chance with its quality.

Encardio Rite has the following advanced facilities that make it one of the leading Geotechnical Instrumentation and Monitoring companies:

(a) R&D Division: Encardio Rite is a leader in technological advancements with cutting-edge software, instrumentation, monitoring, and manufacturing techniques to address the dynamic requirements of the evolving construction and environmental sectors.

(b) Quality: Geotechnical Testing Services are essential to have consistent quality services with reliable products, in compliance with the ISO-9001:2015 quality systems conforming to international standards.

(c) Production: Besides the R&D unit, the company boasts state-of-the-art manufacturing and geotechnical testing facilities, equipped with the best of tools and technology including electron beam welding and load cell calibration facilities up to 15,000 kN.

What Are The Different Types Of Geotechnical Monitoring Services?

Geotechnical Monitoring Services

Geotechnical Monitoring ServicesGeotechnical Services is a huge umbrella that includes all sorts of monitoring carried out at pre-construction, during construction, and post-construction stages. It can include monitoring of tunnels, boreholes, foundations, deep excavations, railways, seaports, airports, bridges, dams, landslide-prone areas, groundwater levels, etc.

The construction phase must have negligible risks which is why a wide range of sensors with advanced database management is required. The monitoring system promotes the monitoring of sub-surface and surface parameters like water level, stress, strain, piezometric pressure, load, lateral deformation, joint openings, cracks, settlement, convergence, tilt, etc. manually and automatically.

The monitored data is constantly provided either online or through evaluation reports to the construction contractor and consultants. This facilitates work in the safe zones and takes corrective actions where there is a possibility of any risks.

Let us have a look at all the geotechnical monitoring services provided by any geotechnical instrumentation and monitoring company including Encardio Rite.

Structural Monitoring

Structural Monitoring

Structural MonitoringThe online web-based structural monitoring services and geotechnical solutions include:

- Safety of buildings, monuments, and structures during nearby construction activity (like underground tunneling, deep excavation for high-rise buildings, etc.).

- Safety of existing multiple-storey buildings, hotel complexes, corporate offices, and buildings of critical importance.

- Safety of old and depleted buildings and structures subject to long-term movement or degradation of materials.

- Safety of monuments and structures of historical importance.

- Safety of buildings and structures in landslide-prone areas.

The monitoring of new construction includes:

- Advanced Geotechnical Services include verification of the hypothesis and the assumption of design parameters.

- Monitoring safety during construction

- Measuring the change in parameters during construction

- Ensuring that the interface of construction with adjacent structures and foundations is sound.

- Certifying the performance of the new construction/excavation.

Also Read: A Guide on Structural Health Monitoring (SHM)

Rail/Road, Metro. & Sewer Tunnels Monitoring

Sewer Tunnels Monitoring

Sewer Tunnels MonitoringFor tunnels, instrumentation and monitoring are beneficial at every stage of its lifecycle:

During the design stage, instrumentation installed in the exploratory tunnels and boreholes gives information regarding the existing ground conditions which in turn helps in optimizing the design. The Geotechnical Investigation confirms the design and monitoring plan.

During the construction stage, instrumentation gives information on how the design is actually performing during execution. In case certain assumptions were made during the design stage, the instrumentation data will determine if these are indeed correct.

If required, changes in design could be made at an early stage saving time and money on remedial measures later. Instrumentation carried out from the surface on the alignment gives data for the surface and subsurface conditions. Instrumentation is also done on the structures on the surfaces that are likely to be affected by the tunnel construction.

Long-term geotechnical monitoring services during the operational stages of the tunnel ensure its safety, determining the effects of any natural calamity (like an earthquake) on its structural integrity. Geotechnical investigation for tunnels helps in planning and optimizing the maintenance schedules.

Read More: Science Behind The Megastructures: Gotthard Base Tunnel

Online Monitoring Of Landslides/Slope Stabilisation

Monitoring Of Landslides

Monitoring Of LandslidesIn general, the following steps can be adopted in landslide-prone areas:

- Monitoring slope to detect any sign of instability. Geotechnical Solutions can then be instituted before alarm conditions are generated.

- Stabilizing slopes that need corrective action using appropriate slope stabilization technique(s).

- Devising an online (near real-time) monitoring program to verify that stability of the slope is achieved.

A good prediction and forewarning system, when implemented with effective efforts to control and mitigate landslides, can drastically reduce the destruction caused by landslides. Unstable slopes require monitoring systems that can be accessed remotely and provide an immediate warning in case of failure.

Advances in geotechnical instrumentation, surveying technologies, and data transmission systems now make it possible to monitor these slopes conveniently and economically. Remote (near real-time) monitoring of slope movement and other parameters potentially affecting it can be a correct approach for risk mitigation in unstable or potentially unstable slopes.

Landslide problems, present or expected in the future, require an engineering geologist to evaluate the type of landslide and take corrective measures based on collected data and experience gained to tackle similar problems. The solution should be based on a well-thought-out working hypothesis taking into consideration the cost involved and effectiveness of the efforts put in.

Groundwater Level Monitoring

Groundwater is among the country’s most precious resources. For any program of efficient water management to be successful, continuous monitoring of water levels in the groundwater is necessary. Groundwater and Geotechnical Problems are very prominent in every place. Reliable and accurate groundwater data is required well in time, to assess groundwater conditions such that adverse situations like drought and loss of pumpage in agriculture and domestic water supply can be efficiently handled.

However, the groundwater monitoring task becomes gigantic and expensive when the number of sites and parameters to be monitored increases. Automated monitoring systems are the best geotechnical software solutions that provide data from different parts of the Country at a remote central location in near real-time.

The primary objective of groundwater monitoring on such a large scale is to record the response of the ground regime to the natural and anthropogenic stresses of recharge and discharge parameters with reference to geology, climate, land use pattern, and hydrologic characteristics.

Read more: Groundwater Level Monitoring & Piezometric Pressure

Monitoring Of Diaphragm Wall Displacement & Associated Ground Movement

Wall Displacement

Wall DisplacementDeep excavation is carried out before the construction of structures like high-rise buildings, underground garages, and underground mass transport systems operating at several levels.

In many such cases, a diaphragm wall is one of the best solutions. Excavation in soft ground induces ground movement. This may damage the adjacent existing sensitive structures. Deformation must be limited to acceptable levels in a deep excavation. Monitoring of the zone of influence is crucial for the safety of the construction work.

Monitoring Of Bridges

Monitoring Of Bridges

Monitoring Of BridgesFor bridges, it is recommended that structural health be continuously monitored to ensure proper maintenance and safety of man and material.

The collapse of a bridge is often preceded by a change in the tilt of affected areas. The comprehensive geotechnical instrumentation is effectively used to online monitor the different types of structures to give timely warnings on impending danger. The purpose is to assist and inform the owner/designer/contractor/architect about the continued performance of structures under gradual or sudden changes to their state.

The main geotechnical problems affecting the performance are degradation of structure with age, undue settlement/tilt due to soil conditions or nearby construction activity, vibrations due to traffic, groundwater level, atmospheric conditions, and movement of slopes in hilly areas, etc. This may be reflected in abnormal changes in tilt and settlement values.

Read more: Structural Monitoring – Bridges

Monitoring Consolidation Of Soft Soil

Monitoring Consolidation Of Soft Soil

Monitoring Consolidation Of Soft SoilConsiderable settlement may occur when constructing projects such as highway embankments, bridge approaches, dykes, dams, large storage areas, tanks, airport runways, or buildings on soft compressible soil, due to the consolidation of soil under the superimposed load.

To avoid serious and potentially expensive problems due to such settlement, it is desirable to cause the consolidation to occur at the outset of the project, and in the shortest possible time during the construction period.

Construction of a facility on top of a soft soil foundation will normally be delayed until there is an assurance that it will not be damaged by the settlement that occurs during subsequent consolidation. If the predicted delay is not acceptable, the time required for consolidation can be reduced by surcharging and/or by the installation of vertical drains.

Seepage Monitoring In An Open Channel

Seepage Monitoring

Seepage MonitoringSeepage of water through, around, or under a dam is expected in all embankment dams and even in concrete dams. The quantity of seepage, the seepage path, and the velocity of seepage water are of great concern in analyzing the structural behavior of a dam.

The quantity of seepage is important for the following reasons:

- A large quantity of seepage around a dam (through the abutments), under a dam (through the foundation), and in some cases, through the dam itself, may dissolve some of the chemical constituents of the rock or soil material present at those locations. The larger the seepage, the greater the dissolution. This, in turn, provides an enlarged seepage path which results in even greater seepage. Dams found on certain evaporites like gypsum are especially affected by this problem.

- A large quantity of water moving through, around, or under a dam results in completely saturated soils and rock in the seepage areas, excessive hydrostatic uplift pressure, as well as softening and weakening of the soil and rock.

- An excessive quantity of seepage may in extreme cases, compromise the storage capability of the reservoir.

The location of the seepage paths is of concern because:

- If the majority of the seepage water is confined to only a few discrete seepage paths and the velocity of the seepage is sufficiently high, then progressive erosion of particles of soil may occur resulting in a piping-type failure of the dam.

- Seepage water in sufficient quantity in a few paths may result in concentrated dissolution in those areas.

The velocity of movement of seepage water is important because:

- The greater the velocity, the greater the chance of particles being eroded in the seepage path. Larger velocity can result in increasingly larger particles being moved and piping failure is more likely to occur.

Embankment dams should as a consequence have provisions for:

- Determination of seepage source

- Reliable measurement of seepage quantity

- Evaluation of water quality of seepage flow, in relation to the materials transported with the flow

- Indication of pore pressure in an embankment, foundation, and the abutments

- Seepage monitoring is probably the single most important form of performance observation for an embankment dam.

- Some quantity of seepage is unavoidable and if not properly channeled, is a threat to the dam. Both the quality and quantity of seepage are of importance.

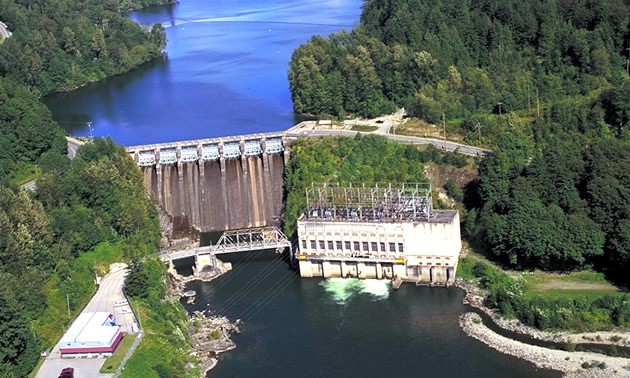

Monitoring Of Dams

Monitoring Of Dams

Monitoring Of DamsMonitoring a dam is essential to understand the foundation and structural behavior both during the construction and operation of the dam. Geotechnical Monitoring Services and Instrumentation plays a key role in safety monitoring for dams and people, providing necessary information on the performance of the dam and detecting problems at an early and preventable stage.

The geotechnical survey scope of work and nature of instrumentation depends not only on the complexity of the dam and the size of the reservoir but also on the potential for loss of life and property downstream. This information is critical for the dam owner who is directly responsible for any consequences of a dam failure.

Safe operations of the dam are an important matter of economic benefit and public safety. Catastrophic dam failure can threaten life and property downstream.

Read more: Instrumentation & Structural Monitoring of Dams

Monitoring Of Nuclear Power Plants

Monitoring Of Nuclear Power Plants

Monitoring Of Nuclear Power PlantsFor Nuclear Power Plants, it is strongly recommended that structural health is continuously monitored to ensure the following:

- Safety of personnel, materials, nearby communities, and the environment.

- Compilation of long-term and reliable data on the various elements of the plant especially foundations, anchoring systems, and containment structures.

- Data to determine the effects of natural calamities such as earthquakes, cyclones, flooding, etc. on the structure.

- Data to plan and schedule predictive and preventive maintenance programs for the plant.

Different Types Of Geotechnical Instrumentation

Types Of Geotechnical Instrumentation

Types Of Geotechnical InstrumentationA wide variety of instruments are used to carry out geotechnical monitoring, geodetic surveys, structural monitoring, as well as, environmental monitoring. The most common geotechnical instrumentation provided by Encardio Rite includes:

Web Data Monitoring Service (WDMS)

The heart of the online structural monitoring instrumentation systems is the Data Collection and Transmission Service offered by Encardio Rite to users anywhere in the World. Encardio Rite offers Data Loggers with GPRS/GSM Transmission, Data Loggers with RF Transmission, Nodes, and Gateways, Readout Units, and a Control Box.

The Data Loggers with GPRS/GSM Transmission are available in different variants to suit the particular application areas and geotechnical needs. These include:

- Model ESDL-30 multi-channel data logger for a digital sensor.

- Model ESCL-12VT single-channel data logger for VW sensors.

- Model ESCL-10VT single-channel data logger for groundwater and rainfall monitoring (with in-built barometric sensor).

The Nodes and Gateway Range include Vibrating Wire Node, Analog Node, Digital Node, Relay Node, and Gateway. The Portable Read-out Units are available for VW sensors and analog sensors.

Read more: Type of Data Loggers and How Do They Work?

Tilt Meters

Tilt Meters

Tilt MetersTo monitor the tilt of buildings that may be caused due to the differential ground settlement, a suitable sensor is the Tiltmeter. The tilt meter should ideally be installed at an indoor location or in the shade to prevent the effect of large temperature fluctuations on the monitored results. Users may use two or more tiltmeters to monitor the tilt of buildings with time.

Reading is retrieved in the morning hours when temperature-induced stresses in the buildings are minimal.

The picture below shows a biaxial tiltmeter with an ESDL-30 data logger installed on a building.

ESDL-30 data logger

ESDL-30 data loggerFor safety monitoring of existing structures, two or more such systems may be mounted at proper locations, data being available online with alarms through Encardio Rite Web Monitoring Services.

For buildings and structures built on hills and mountains, this is a good low-cost service for monitoring their stability with time. It may give forewarning of ground movement during rainfalls. There are also Analog Tiltmeters, Portable Tilt meters, Digital Tiltmeters, and Box-type tiltmeters among the other collections.

Read more: What Are Tiltmeters And Where Are They Used?

Crack Meters/Crack Gauges/Displacement Meters/Joint Meters

Crack Meters

Crack MetersWith time cracks develop in buildings, structures, and monuments. Monitoring change in its width provides important information. To online monitor changes in crack width, a suitable sensor is the Model EDJ-40V surface crack meter. Users may use several of these at representative locations to monitor the development of cracks in buildings with time.

The image below shows crack gauges being mounted on the dome of a Basilica at Trino, Italy for online web-based monitoring. Several tilt meters were also mounted in this structure for online monitoring.

Structure for online monitoring

Structure for online monitoringFor manual monitoring of cracks, Encardio Rite Models EDJ-40C and EDJ-41M crack gauges are available.

Inclinometers

In-place inclinometers (IPI) are used for continuous monitoring of lateral movement of the ground at construction sites involving deep excavation. Such lateral movement of the ground may affect the safety of adjoining structures.

Inclinometers

InclinometersFor online monitoring of lateral movement in boreholes, Encardio Rite offers Model EAN-52MV In-place Inclinometer System with SDI-12 interface sensors.

The digital inclinometer consists of a traversing-type digital tilt-sensing probe that is connected to a reel unit kept at the borehole top. The reel consists of a winding reel that holds the cable and a wireless Bluetooth relay unit that sends the digital probe data to the mobile phone. A rechargeable battery in the reel unit supplies power to the whole system.

Read more: Tiltmeter: How Does it Work, Installation, & How to Read

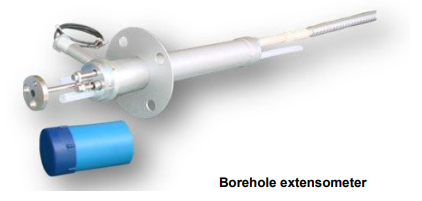

Borehole Extensometer

Encardio Rite Models EDS-71V single channel and EDS-70V 2-6 channel borehole extensometer (BHE) is extensively used for online monitoring of sub-surface ground settlement during construction activity. In case the BHE is mounted in a horizontal borehole, it gives important information on lateral movement.

Borehole Extensometer

Borehole ExtensometerFor manual monitoring with a micrometer depth gage, Encardio Rite Models EDS-64U/D single channel and EDS-63U/D 2-6 channel BHE are available.

Piezometers

Piezometers

PiezometersEncardio Rite Model EPP-30V piezometer is recommended for online monitoring of groundwater pressure/level near the construction site, between the building and excavation, and underground works.

An online piezometric pressure monitoring system provides very important information on safety, especially during the rainy season for any structure built on a hill. The data is transmitted to a central server through GSM/GPRS for Web Data Monitoring Service by Encardio Rite.

Read More: Piezometers: Types, Functions, & How it works?

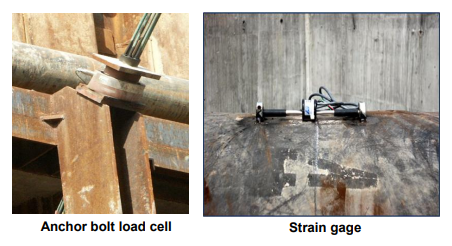

Strain Gauges and Load Cells

Strain Gauges and Load Cells

Strain Gauges and Load CellsConstruction of deep foundations may result in lateral movement and settlement of the surrounding structures in case the latter falls in the zone of influence of the construction activity. This may necessitate the construction of a diaphragm wall or sheet piles around the area to be excavated.

During excavation, struts or anchors may be used to contain the lateral movement. For monitoring of struts or anchors, the following sensors are available from Encardio Rite:

- EDS-20V-AW arc weldable strain gage for monitoring stress in struts

- ELC-32V center hole anchor bolt load cell

Read More:

Strain Gauge: Principle, Types, Features and Applications

Load Cells: Types, How It Works, Applications, & Advantages

Calibrated Catch Container

For a relatively low flow rate, the simplest method for monitoring the rate of seepage is by using a calibrated catch container.

To use a catch container, the drain water should either be directed through a pipe with an open end or through a channel constructed with an overhang and a vertical drop. The calibrated catch container is then placed in a position to catch the water and the time required to do so is measured with a stopwatch. The catch container should preferably be made of stainless steel or some suitable plastic material that does not corrode easily.

Flow Meter

Seepage water collected in a toe drain or drain trench of a dam is taken through open channels or pipes for discharge downstream of the dam. The quantity of this flow can be determined by measuring the velocity of the water.

There are many methods of measuring the velocity of the water. Some use the pivot tube principle for this purpose. Others use propeller-type rotary devices electromagnetic sensors or acoustic velocity meters for measurement of the velocity.

In case the seepage water is directed through a pipe, an easy method of determining the flow is to mount a suitable orifice plate in the pipe and measure the pressure drop across it by a differential pressure transmitter.

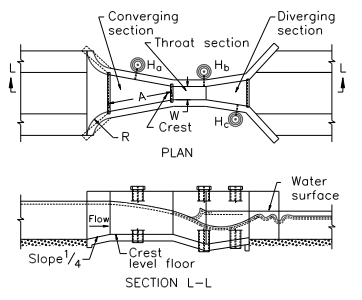

Parshall Flumes

Parshall Flumes

Parshall FlumesA flume is a specially shaped open channel flow section, somewhat like a venturi. The flow is constricted by a converging section over the crest of the flume. This produces a differential head which can be related to the discharge.

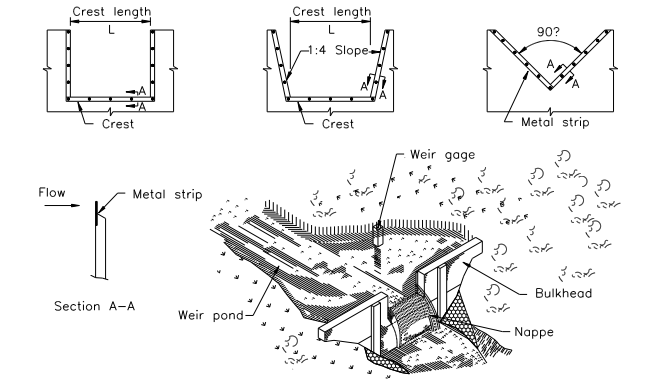

Weir

Weir

WeirThe weir is one of the oldest, simplest, and most reliable devices used to measure the quantity of flow of water in a seepage. The weir normally used is the rectangular or 90° V-notch type. In case of a low flow rate, a V-notch weir with an angle of less than 90° may be used. Sometimes, a trapezoidal weir is used. In some rare cases, a parabolic or circular weir is used.

The discharge over a thin plate weir is a function of the water head on the weir, the size and shape of the discharge area, and an experimentally determined discharge coefficient which takes into account the head of the water over the weir, the geometry of the approach channel, the weir, and the physical properties of water and characteristics of flow.

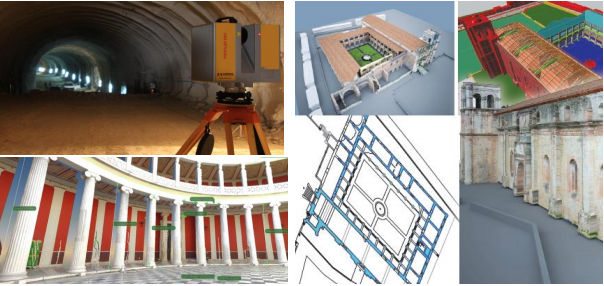

Laser Scanning

Laser Scanning

Laser ScanningLaser scanning is a new mapping method for geometric documentation of buildings, architectural and archaeological monuments, construction projects (such as tunnels, bridges, dams, etc.), or any other construction that requires a high degree of analysis, is inaccessible or difficult to access or must not be touched. The Geotechnical Software Solution is based on a very dense three-dimensional coordinate map of the surface areas to be mapped in fast output of several thousand to one million points per second.

Laser Scanning is a measuring method where a surface is scanned using laser technology. It analyzes all kinds of objects and collects data on their shape and possibly their appearance (e.g. color). The collected data can then be used to construct digital, two-dimensional drawings or three-dimensional models useful for a wide variety of applications. Three-dimensional laser scanners can measure the same quantities as a total station (horizontal and vertical angles and distances).

Instead of providing these polar coordinates for targets selected by the instrument’s operator, the laser scanner measuring head turns to angles by predefined angle steps measuring the distance to the object point lying in that direction. Modern laser scanners have very small angle steps resulting therefore in extremely high spatial resolutions. This feature is a huge advantage because of the fact that it can record huge numbers of points with high accuracy in a relatively short period of time. The Geotechnical Software Solution is offered by Encardio Rite.

Laser Scanning of a tunnel is shown in the image below:

Laser Scanning of a tunnel

Laser Scanning of a tunnelAutomated Monitoring System (AMS)

Automated Monitoring System (AMS)

Automated Monitoring System (AMS)An automated measuring system for the total displacements (3D) in real-time in zones where the TBM tunneling or other tunnel/station/shaft works might give rise to settlements to sensitive buildings and other structures is described.

The geotechnical solution consists of a series of networked robotic total stations and prisms located along the Project’s alignment. This system ensures valuable and timely monitoring of the displacements, providing high measurement density, simultaneous wireless transmission, and entry of the results into the database system to ensure minimal time between their reading and their evaluation.

The geotechnical assessments are made with a series of automatic electronic total stations of high precision, which will record the displacement of reflecting prisms on the ground surface and on buildings.

Geodetic Targets And Survey Markers

Geodetic Targets And Survey Markers

Geodetic Targets And Survey MarkersGeodetic Targets are designed to measure deformation in dams, roads, tunnels, bridges and overpasses, multi-story and historical buildings, foundations, mining – exploitation, landslides, and sloping, and in earthquake-prone regions.

Geotechnical Survey Markers are placed to mark significant survey points on the earth’s surface during geodetic and land surveying.

Seismograph And Accelerometer

Seismometers are designed to measure ground movements/vibrations caused by earthquakes, excavations, boring, drilling, etc. The Geotechnical testing methods record these movements as graphs often known as seismographs. Accelerometers, on the other hand, are used to measure static or dynamic accelerating forces.

Encardio Rite’s Model EADA-350F Accelerometer with digital output is the first ever accelerometer to be manufactured in India under the “Make In India” initiative”.

The Accelerometer with digital output is shown below:

Seismograph And Accelerometer

Seismograph And AccelerometerModel ESDA-120S Broadband Seismometer with digital output is shown in the image below:

Model ESDA-120S Broadband Seismometer

Model ESDA-120S Broadband SeismometerThis was all about the geotechnical monitoring and instrumentation along with the different services, solutions, and types of instruments used while monitoring. We hope that you found this information pretty useful.

For more such articles, keep watching this space. If you have any doubts or questions, feel free to comment below.